What Are The Types Of Industrial Jacketed Kettle?

Cooking Mixer News /

06/28/2021

What are the types of industrial jacketed kettle?

Jacketed kettle product introduction

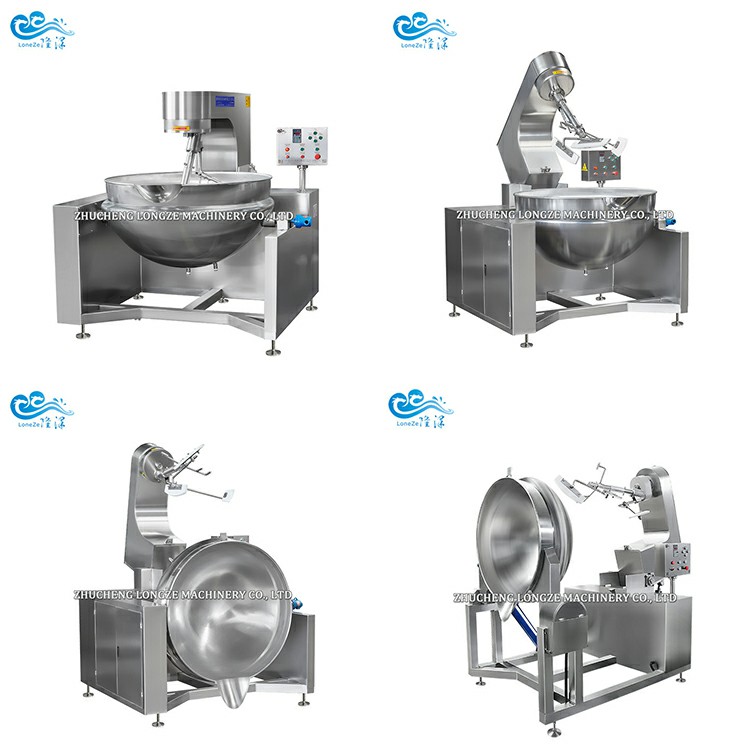

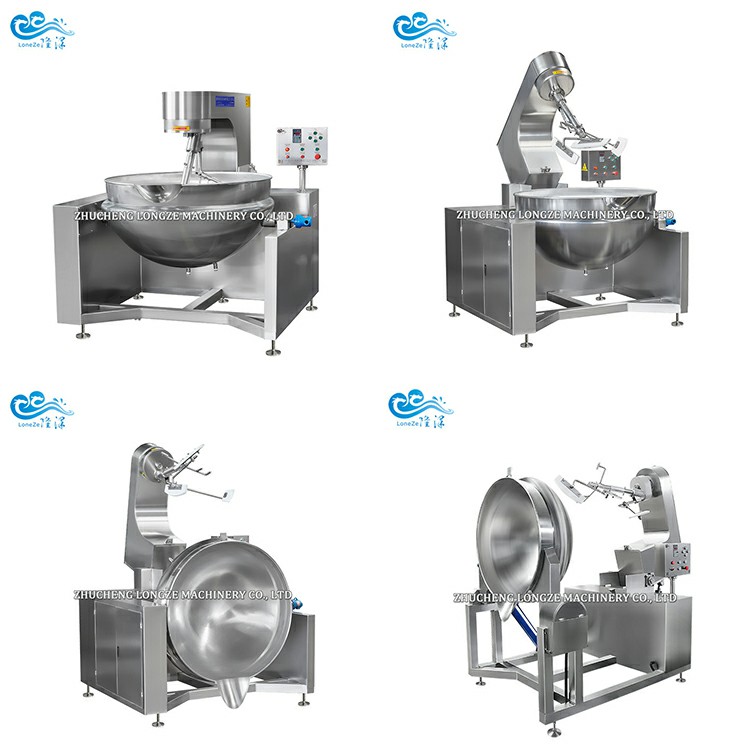

Jacketed kettle is also known as steam pot, cooking pot, and jacketed steam pot. It usually consists of a pot body and legs. The pot body is a double-layer structure composed of an inner and outer spherical pot body, and the middle layer is heated by steam. There are fixed, tiltable, stirring and other styles.

The jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, easy control of heating temperature, beautiful appearance, easy installation, convenient operation, safety and reliability.

jacketed kettles are widely used in the processing of various foods, and can also be used in large restaurants or canteens to boil soup, cook, stew, porridge, etc. It is a good equipment for food processing to improve quality, shorten time, and improve working conditions.

Classification of industrial jacketed kettles:

1. According to the structure, it can be divided into: tiltable jacketed kettle, vertical (fixed) jacketed kettle structure

2. According to the heating method, it is divided into: electric heating jacketed kettle, steam heating jacketed kettle, gas heating jacketed kettle, electromagnetic heating jacketed kettle.

3. According to the needs of the process, the equipment with stirring or without stirring is adopted.

4. According to the sealing method, the jacketed kettle can be divided into: no cover type, flat cover type and vacuum type;

Overall structure of industrial jacketed kettle:

The fixed type is mainly composed of a pot body and supporting feet;

The tilting type is mainly composed of a pot body and a tilting rack;

The stirring type is mainly composed of a pot body and a stirring device.

Pot body

It is a double-layer structure composed of inner and outer spherical pots, and the middle layer is heated by steam.

Feet

(A) Vertical jacketed kettle: triangular pyramid type and round tube type.

(B) Tilting sandwich pot: channel steel bracket type.

Material

(A) The inner pot is stainless steel (SUS304/SUS316L), and the outer pot is carbon steel (Q235-B); the outside is coated with anti-rust paint.

(B) The inner and outer pots are all stainless steel (SUS304/SUS316L).

Features of industrial jacketed kettle:

Efficient heating

The jacketed boiler uses a certain pressure of steam as the heat source (electric heating can also be used). The jacketed boiler has the characteristics of large heating area, high thermal efficiency, uniform heating, short liquid boiling time, and easy control of heating temperature.

Safe and convenient

The inner pot (inner pot) of the jacketed kettle is made of acid-resistant and heat-resistant austenitic stainless steel, equipped with pressure gauge and safety valve, beautiful appearance, easy installation, convenient operation, safe and reliable.

Parameters of electric heating jacketed kettle

Equipment type Heated area (㎡) Heat transfer oil added amount (kg) Power and number (KW×Z)

50L 0.45 20 3×3

100L 0.58 30 4×3

150L 0.88 45 5×3

200L 1.13 55 6×3

300L 1.43 65 6×3

400L 1.75 75 8×3

500L 2.00 120 9×3

600L 2.30 160 9×3

Note: The amount of heat transfer oil must be 4/5 full in the interlayer.

The electric heating jacketed kettle is mainly composed of a pot body and a bracket. The pot body is a double-layer structure composed of an inner-outline pot body, and the middle interlayer is filled with heat-conducting oil or water. The electric heating jacketed kettle uses 380V power as the heat source. The jacketed kettle is equipped with electric heating rods, electric thermocouples and heat transfer oil (self-matching), which can reach up to 320 degrees. It is controlled by an electric control box and equipped with a temperature control system. The electric heating jacketed kettle has a large heating area, uniform heating, high thermal efficiency, short liquid boiling time, and easy heating temperature control.

Structure type

Fixed/tilting/stirring

Remarks: The volume, interlayer working pressure, motor power, stirring blade structure, etc. can be customized according to customer specific requirements.

Technical performance

Electric heating jacketed kettle

1. Volume: 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, 1000L.

2. Structure: It can be divided into tilting and vertical structures, with and without mixing according to the process requirements.

3. Pot body material: ①Inner pot body stainless steel (SUS304), jacket and bracket carbon steel (Q235-B) coated with anti-rust paint; ②The inside and outside are all stainless steel.

4. Pot with stirring device: stirring at the center of the top, the output shaft of the reducer and the shaft of the stirring paddle are connected by a looper, which is convenient for disassembly and cleaning.

5. Stirring speed: 36r/min (a certain speed can be selected according to customer requirements); stirring paddle form: ordinary stirring (anchor type) and bottom scraping stirring.

6. Foot form: ①Vertical pot body: triangular pyramid type, round tube type; ②Tiltable pot body: trough-shaped bracket type.

7. Equipment configuration: dial pointer thermometer, steam inlet, discharge port, etc. (vertical structure).

8. The tiltable jacketed kettle body can tilt up to 90°, and the tilting method is manual turning.

Note: Jacket working pressure, motor power, heating power, stirring blade structure, etc. can be customized according to customer's special requirements.

Installation steps of jacketed kettle:

1. Tighten the two setscrews of the support frame. When shaking the pot, the inlet and outlet pipes at both ends are not allowed to rotate with the pot.

2. After the installation is completed, the agitated jacketed kettle should be tested for an empty car and can only be put into production after the transmission components are running normally.

3. After air intake, if there is air leakage at the joint, tighten the nut until it does not leak.

Precautions for the use of steam jacketed kettle:

1. Use the steam pressure and not exceed the rated working pressure for a long time.

2. When entering steam, open the steam inlet valve slowly until the pressure is needed. The shut-off valve at the condensate outlet, if a trap is installed, should always be opened; if there is no trap, open the valve first until there is When the steam overflows, turn the valve down again, and keep the opening degree until a small amount of steam overflows.

3. The safety valve can be adjusted according to the pressure of the user's own steam.

4. During the use of the steam boiler, you should always pay attention to the change of steam pressure, and adjust it in time with the steam inlet valve.

5. After stopping the air intake, the straight mouth cock at the bottom of the pot should be opened, and the remaining water should be discharged.

6. Tilting and stirring jacketed kettles should be oiled at all rotating parts before each shift; cooked vegetable oil is recommended for the parts on the surface of the stirring jacketed kettle; 30#--40# machinery is used everywhere else oil.

Industrial steam jacketed boiler maintenance:

1. The steam inlet and outlet pipe joints leak steam. When tightening the nut does not solve the problem, add or replace the packing.

2. The pressure gauge and safety valve should be checked regularly, and if there is any malfunction, they should be replaced and repaired in time.

3. After 50 hours of use, the gearbox should be disassembled to drain the lubricating oil, rinsed with kerosene or diesel, and added 30#-40# clean oil. After 150 hours of use, change the oil for the second time, depending on the specific situation in the future. , Change the oil every 1000 hours of use.

4. If the anti-rust oil peels off, it should be painted in time, and the paint of the outer pot should be painted. X55-3 aluminum powder vinyl water-resistant paint is recommended.

5. After the pot has been used for 5 years, it is recommended to conduct a safety water pressure test, and the interval between subsequent water pressure tests shall be carried out according to the requirements of the local technical departments.

The pressure P water of the hydraulic test is determined according to the following conditions:

When the rated working pressure P is less than 0.6MPa, P water = 0.15MPa;

When the rated working pressure P=0.6-0.8MPa,

P water = P amount + 0.3MPa

6. The outer pot body of this pot is made of 4.0~5.5mm thick steel plate, steel grade A3. When the outer pot is reduced to less than 2mm after years of corrosion, it should be discontinued.

7. The welding of the stainless steel of this pot and the welding of the joints of other stainless steel materials should use stainless steel electrodes Ao 102, Ao 107, Ao 132, and Ao 137. Other grades should not be used.

Jacketed kettle product introduction

Jacketed kettle is also known as steam pot, cooking pot, and jacketed steam pot. It usually consists of a pot body and legs. The pot body is a double-layer structure composed of an inner and outer spherical pot body, and the middle layer is heated by steam. There are fixed, tiltable, stirring and other styles.

The jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, easy control of heating temperature, beautiful appearance, easy installation, convenient operation, safety and reliability.

jacketed kettles are widely used in the processing of various foods, and can also be used in large restaurants or canteens to boil soup, cook, stew, porridge, etc. It is a good equipment for food processing to improve quality, shorten time, and improve working conditions.

Classification of industrial jacketed kettles:

1. According to the structure, it can be divided into: tiltable jacketed kettle, vertical (fixed) jacketed kettle structure

2. According to the heating method, it is divided into: electric heating jacketed kettle, steam heating jacketed kettle, gas heating jacketed kettle, electromagnetic heating jacketed kettle.

3. According to the needs of the process, the equipment with stirring or without stirring is adopted.

4. According to the sealing method, the jacketed kettle can be divided into: no cover type, flat cover type and vacuum type;

Overall structure of industrial jacketed kettle:

The fixed type is mainly composed of a pot body and supporting feet;

The tilting type is mainly composed of a pot body and a tilting rack;

The stirring type is mainly composed of a pot body and a stirring device.

Pot body

It is a double-layer structure composed of inner and outer spherical pots, and the middle layer is heated by steam.

Feet

(A) Vertical jacketed kettle: triangular pyramid type and round tube type.

(B) Tilting sandwich pot: channel steel bracket type.

Material

(A) The inner pot is stainless steel (SUS304/SUS316L), and the outer pot is carbon steel (Q235-B); the outside is coated with anti-rust paint.

(B) The inner and outer pots are all stainless steel (SUS304/SUS316L).

Features of industrial jacketed kettle:

Efficient heating

The jacketed boiler uses a certain pressure of steam as the heat source (electric heating can also be used). The jacketed boiler has the characteristics of large heating area, high thermal efficiency, uniform heating, short liquid boiling time, and easy control of heating temperature.

Safe and convenient

The inner pot (inner pot) of the jacketed kettle is made of acid-resistant and heat-resistant austenitic stainless steel, equipped with pressure gauge and safety valve, beautiful appearance, easy installation, convenient operation, safe and reliable.

Parameters of electric heating jacketed kettle

Equipment type Heated area (㎡) Heat transfer oil added amount (kg) Power and number (KW×Z)

50L 0.45 20 3×3

100L 0.58 30 4×3

150L 0.88 45 5×3

200L 1.13 55 6×3

300L 1.43 65 6×3

400L 1.75 75 8×3

500L 2.00 120 9×3

600L 2.30 160 9×3

Note: The amount of heat transfer oil must be 4/5 full in the interlayer.

The electric heating jacketed kettle is mainly composed of a pot body and a bracket. The pot body is a double-layer structure composed of an inner-outline pot body, and the middle interlayer is filled with heat-conducting oil or water. The electric heating jacketed kettle uses 380V power as the heat source. The jacketed kettle is equipped with electric heating rods, electric thermocouples and heat transfer oil (self-matching), which can reach up to 320 degrees. It is controlled by an electric control box and equipped with a temperature control system. The electric heating jacketed kettle has a large heating area, uniform heating, high thermal efficiency, short liquid boiling time, and easy heating temperature control.

Structure type

Fixed/tilting/stirring

Remarks: The volume, interlayer working pressure, motor power, stirring blade structure, etc. can be customized according to customer specific requirements.

Technical performance

Electric heating jacketed kettle

1. Volume: 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, 1000L.

2. Structure: It can be divided into tilting and vertical structures, with and without mixing according to the process requirements.

3. Pot body material: ①Inner pot body stainless steel (SUS304), jacket and bracket carbon steel (Q235-B) coated with anti-rust paint; ②The inside and outside are all stainless steel.

4. Pot with stirring device: stirring at the center of the top, the output shaft of the reducer and the shaft of the stirring paddle are connected by a looper, which is convenient for disassembly and cleaning.

5. Stirring speed: 36r/min (a certain speed can be selected according to customer requirements); stirring paddle form: ordinary stirring (anchor type) and bottom scraping stirring.

6. Foot form: ①Vertical pot body: triangular pyramid type, round tube type; ②Tiltable pot body: trough-shaped bracket type.

7. Equipment configuration: dial pointer thermometer, steam inlet, discharge port, etc. (vertical structure).

8. The tiltable jacketed kettle body can tilt up to 90°, and the tilting method is manual turning.

Note: Jacket working pressure, motor power, heating power, stirring blade structure, etc. can be customized according to customer's special requirements.

Installation steps of jacketed kettle:

1. Tighten the two setscrews of the support frame. When shaking the pot, the inlet and outlet pipes at both ends are not allowed to rotate with the pot.

2. After the installation is completed, the agitated jacketed kettle should be tested for an empty car and can only be put into production after the transmission components are running normally.

3. After air intake, if there is air leakage at the joint, tighten the nut until it does not leak.

Precautions for the use of steam jacketed kettle:

1. Use the steam pressure and not exceed the rated working pressure for a long time.

2. When entering steam, open the steam inlet valve slowly until the pressure is needed. The shut-off valve at the condensate outlet, if a trap is installed, should always be opened; if there is no trap, open the valve first until there is When the steam overflows, turn the valve down again, and keep the opening degree until a small amount of steam overflows.

3. The safety valve can be adjusted according to the pressure of the user's own steam.

4. During the use of the steam boiler, you should always pay attention to the change of steam pressure, and adjust it in time with the steam inlet valve.

5. After stopping the air intake, the straight mouth cock at the bottom of the pot should be opened, and the remaining water should be discharged.

6. Tilting and stirring jacketed kettles should be oiled at all rotating parts before each shift; cooked vegetable oil is recommended for the parts on the surface of the stirring jacketed kettle; 30#--40# machinery is used everywhere else oil.

Industrial steam jacketed boiler maintenance:

1. The steam inlet and outlet pipe joints leak steam. When tightening the nut does not solve the problem, add or replace the packing.

2. The pressure gauge and safety valve should be checked regularly, and if there is any malfunction, they should be replaced and repaired in time.

3. After 50 hours of use, the gearbox should be disassembled to drain the lubricating oil, rinsed with kerosene or diesel, and added 30#-40# clean oil. After 150 hours of use, change the oil for the second time, depending on the specific situation in the future. , Change the oil every 1000 hours of use.

4. If the anti-rust oil peels off, it should be painted in time, and the paint of the outer pot should be painted. X55-3 aluminum powder vinyl water-resistant paint is recommended.

5. After the pot has been used for 5 years, it is recommended to conduct a safety water pressure test, and the interval between subsequent water pressure tests shall be carried out according to the requirements of the local technical departments.

The pressure P water of the hydraulic test is determined according to the following conditions:

When the rated working pressure P is less than 0.6MPa, P water = 0.15MPa;

When the rated working pressure P=0.6-0.8MPa,

P water = P amount + 0.3MPa

6. The outer pot body of this pot is made of 4.0~5.5mm thick steel plate, steel grade A3. When the outer pot is reduced to less than 2mm after years of corrosion, it should be discontinued.

7. The welding of the stainless steel of this pot and the welding of the joints of other stainless steel materials should use stainless steel electrodes Ao 102, Ao 107, Ao 132, and Ao 137. Other grades should not be used.

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:https://www.firemixer.com/

WhatsApp/Wechat:0086 13153609533

Tel:0086 13153609533

E-mail:rena@loneze.com

Address:Zhucheng Economic Development Zone, Shandong Province, the first five lines west

Contact:Ms. Rena

If you have any question you can contact me ,i can give you the lowest discount.