Use And Maintenance Of The Jacketed Kettle Used In The Kitchen

Cooking Mixer News /

06/28/2021

Use and maintenance of the sandwich pot used in the kitchen

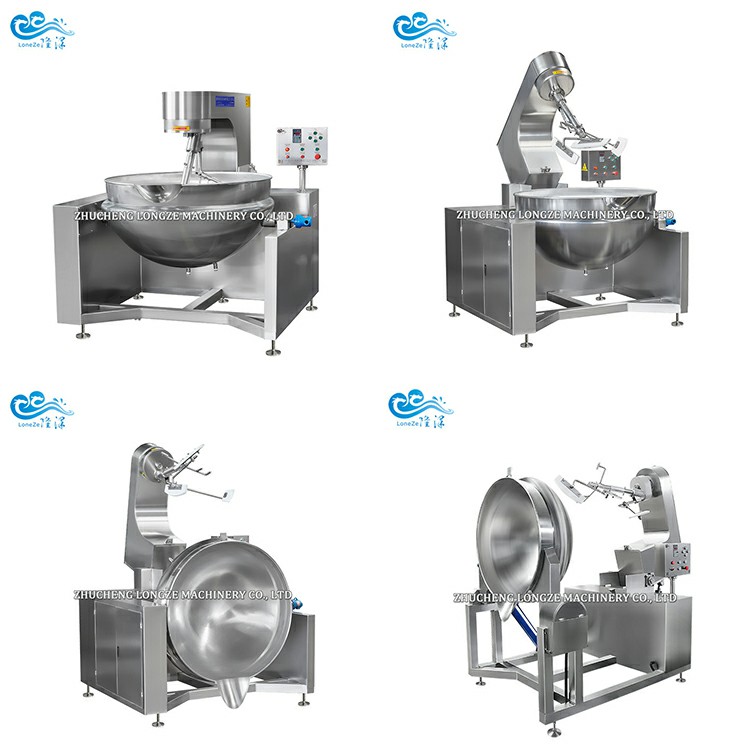

Jacketed kettle are also called cooking jacket kettle pots, which are divided into fixed vertical jacketed kettle, tiltable jacketed kettle, and stirred jacketed kettle. It is used for cooking in large places such as restaurants, canteens, schools, etc. It is widely used, easy to operate, simple, and practical. Different types and materials can be selected according to different products.

Planetary stirring jacketed cooking kettle is suitable for steaming food, boiling syrup, frying vegetables, condiments and baking, etc. It is often used for heating, stirring and frying in catering and food processing or chemical processes. The gas jacketed boiler has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of materials, and easy control of heating temperature.

Maintenance:

1. When unpacking, check whether the product and accessories are consistent with the packing list. During the transportation, whether the product and parts are damaged. If there is any loss or damage, please contact the company in time to solve it.

2. The product has been tested for performance before leaving the factory, and the relative positions of all parts have been installed and adjusted. The user generally only checks it and must not disassemble it at will, so as to avoid improper reinstallation and adjustment, which will affect the performance of the product.

3. The equipment does not need to be fixed, it only needs to be placed on a flat concrete floor.

4. When using a stirred jacketed pot, the power supply should meet the requirements of the stirring structure of the equipment, and the equipment casing must be well grounded to avoid leakage accidents.

5. During installation and use, care should be taken to ensure that the oil inlet pipeline is unblocked and free of obstruction.

6. Tighten the two setscrews on the support frame. When shaking the pot, the oil inlet and outlet pipes at both ends are not allowed to rotate with the pot.

7. Valves are not allowed to be installed at the overflow port.

8. When discharging, first open the lid of the pot, and then turn the hand wheel to tilt the pot body so that the material is discharged from the discharge port.

9. Vertical electric heating jacketed pot. When discharging, the material should be discharged from the outlet of the bottom of the pot.

Heating form This equipment adopts the principle of electromagnetic induction. When the current passes through the electromagnetic coil, an alternating magnetic field is repeatedly cut and changed at the bottom of the pot body, and a ring current is generated to quickly heat the bottom of the pot. The heat transfer principle reheats the material in the pot. This equipment converts electric energy into heat energy to achieve the purpose of heating materials. The heat absorption efficiency is as high as 98%. The peripheral temperature of the pot body is low, not easy to scald, the heating speed is fast, the power saving effect is significant, and the environmental protection and energy saving are pollution-free. . This product can also use other heating forms: steam heating, electric heating heat conduction oil, gas heating, steam heating, etc.

Widely used in hot pot base, chili sauce, red oil, jelly making, candy, lotus paste, bean paste, jam, pastry, beverage, candied fruit, canned food, lotus paste, fruit paste, bean paste, jujube paste, sauce, curry For food processing and brewing, wine making, pharmacy and daily chemical industries, it is used for material melting, disinfection, heating, blanching, pre-cooking, preparation, boiling, steaming and concentration. At the same time, it is also suitable for large hotels, restaurants, hotels, guest houses, restaurants, industrial and mining enterprises, government agencies, and college canteens, as porridge, soup, dumplings, cooking and stew.

Operation and use

1. Inspection equipment: The equipment should be inspected before use. All control and operating parts should be in good condition, and the pot should be in a vertical state. Confirm that the supply gas is consistent with the type of gas indicated on the equipment nameplate. Clean the inner and outer surfaces with detergent until it is cleaned. It can be put into use after it is clean.

2. Adding materials: Add food, water, etc. to the pot.

3. Turn on the power: Press the "motor start" switch, the green button, and the stirrer starts to stir. Choose low speed first, and then choose high speed or low speed according to cooking requirements. It is strictly forbidden to adjust the speed of the reducer when the motor is stopped.

4. Burner ignition: The first step is to confirm that the knobs on the operation panel, the long open flame knob and the ignition rod knob are in the fully closed position, and then open the main gas valve. The second step is to turn on the ignition rod knob, ignite the ignition rod, and insert it into the ignition port at the lower part of the combustion chamber. At the same time, turn on the long open flame knob to ignite the long open burner. The third step is to pull out the ignition rod, close the knob, and place the ignition rod in place. The fourth step is to push down the knobs of the fire plate and turn them to the fully open position. At this time, the fire plate burner will ignite automatically. The inner ring burner should be used first, and the outer ring burner should be used after confirming that the combustion state is good.

5. Firepower adjustment: If you need to use a low fire to cook food, you can turn the inner and outer ring knobs from the fully open position to the low fire position by half a turn, or turn off any burner.

6. End operation: After the food is processed, stop heating, return the main burner knob and the long open flame burner knob to the off position, turn off the gas main knob, and press the "motor stop" switch at the right time, the red button, the stirrer stops stirring , Then turn off the main power supply.

7. Dumping operation:

◆ The dumping operation should be performed after turning off the burner and turning off the power supply! Shake the rotating arm handwheel to turn the blender to the proper position; then shake the tilting pot handwheel, rotate the pot to the proper position, and pour the food into the container.

◆ Turn the water tap out of the pot before pouring the pot!

◆ The tilting operation should be carried out slowly, not too fast or too hastily, so as to avoid splashing and scalding hot soup!

◆ Do not put your hands or other objects in the middle of the moving parts to avoid pinching or jamming!

◆ When dumping the jacketed cooking kettle, operate on the front right side, and do not stand behind to avoid crushing injuries!

Use and operation: (1) Installation

1. Place the equipment in a well-ventilated room during installation. The ground is required to be flat and solid, the size of the ground is appropriate, and there is enough space for personnel to operate; after the equipment is placed in the pre-selected site, the pot body should be leveled by adjusting the fixed feet to ensure stable and reliable work, and fixed with anchor bolts.

2. There should be a trough with unobstructed drainage under the equipment, and cold and hot water pipes should be installed on the side of the pot to facilitate adding water and washing the pot during cooking.

3. Connect the gas pipeline. Before starting the gas piping operation, confirm that the supply gas is the same as the gas used in the jacketed cooking kettle; the connection to the gas pipeline must be carried out by specialized technicians. After the connection is completed, the gas pipeline connection should be leak-checked to ensure that the gas pipeline is tight and leak-proof gas.

4. Adjustment of gas pressure. The gas pressure should be adjusted according to the following table before use. In addition, it should be confirmed that the dynamic pressure of surrounding gas appliances should meet the requirements when they are used at the same time. Gas type Rated working pressure (Pa) Liquefied petroleum gas 2800 Natural gas 2000 Artificial gas 1000 5. Check that it is equipped with a standard power socket that meets the requirements, and that it has a standard grounding protection system and is reliably connected to the grounding bolt of the equipment.

Excellent equipment to improve the quality of food processing, shorten the time and improve the labor environment. In terms of the mixing method, it is divided into two types: scraping bottom mixing and planetary mixing. Different mixing methods can be selected according to the specific products.

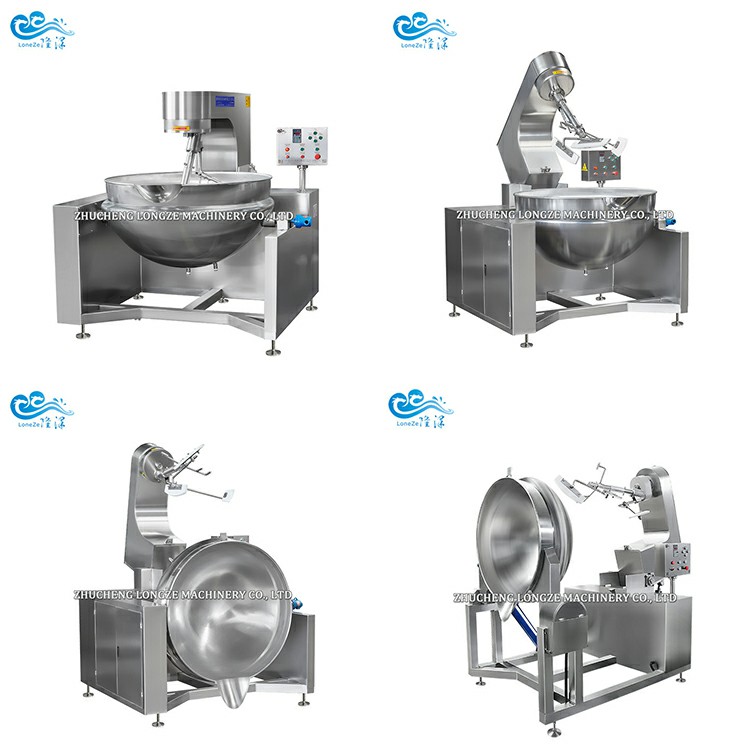

Jacketed kettle are also called cooking jacket kettle pots, which are divided into fixed vertical jacketed kettle, tiltable jacketed kettle, and stirred jacketed kettle. It is used for cooking in large places such as restaurants, canteens, schools, etc. It is widely used, easy to operate, simple, and practical. Different types and materials can be selected according to different products.

Planetary stirring jacketed cooking kettle is suitable for steaming food, boiling syrup, frying vegetables, condiments and baking, etc. It is often used for heating, stirring and frying in catering and food processing or chemical processes. The gas jacketed boiler has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of materials, and easy control of heating temperature.

Maintenance:

1. When unpacking, check whether the product and accessories are consistent with the packing list. During the transportation, whether the product and parts are damaged. If there is any loss or damage, please contact the company in time to solve it.

2. The product has been tested for performance before leaving the factory, and the relative positions of all parts have been installed and adjusted. The user generally only checks it and must not disassemble it at will, so as to avoid improper reinstallation and adjustment, which will affect the performance of the product.

3. The equipment does not need to be fixed, it only needs to be placed on a flat concrete floor.

4. When using a stirred jacketed pot, the power supply should meet the requirements of the stirring structure of the equipment, and the equipment casing must be well grounded to avoid leakage accidents.

5. During installation and use, care should be taken to ensure that the oil inlet pipeline is unblocked and free of obstruction.

6. Tighten the two setscrews on the support frame. When shaking the pot, the oil inlet and outlet pipes at both ends are not allowed to rotate with the pot.

7. Valves are not allowed to be installed at the overflow port.

8. When discharging, first open the lid of the pot, and then turn the hand wheel to tilt the pot body so that the material is discharged from the discharge port.

9. Vertical electric heating jacketed pot. When discharging, the material should be discharged from the outlet of the bottom of the pot.

Heating form This equipment adopts the principle of electromagnetic induction. When the current passes through the electromagnetic coil, an alternating magnetic field is repeatedly cut and changed at the bottom of the pot body, and a ring current is generated to quickly heat the bottom of the pot. The heat transfer principle reheats the material in the pot. This equipment converts electric energy into heat energy to achieve the purpose of heating materials. The heat absorption efficiency is as high as 98%. The peripheral temperature of the pot body is low, not easy to scald, the heating speed is fast, the power saving effect is significant, and the environmental protection and energy saving are pollution-free. . This product can also use other heating forms: steam heating, electric heating heat conduction oil, gas heating, steam heating, etc.

Widely used in hot pot base, chili sauce, red oil, jelly making, candy, lotus paste, bean paste, jam, pastry, beverage, candied fruit, canned food, lotus paste, fruit paste, bean paste, jujube paste, sauce, curry For food processing and brewing, wine making, pharmacy and daily chemical industries, it is used for material melting, disinfection, heating, blanching, pre-cooking, preparation, boiling, steaming and concentration. At the same time, it is also suitable for large hotels, restaurants, hotels, guest houses, restaurants, industrial and mining enterprises, government agencies, and college canteens, as porridge, soup, dumplings, cooking and stew.

Operation and use

1. Inspection equipment: The equipment should be inspected before use. All control and operating parts should be in good condition, and the pot should be in a vertical state. Confirm that the supply gas is consistent with the type of gas indicated on the equipment nameplate. Clean the inner and outer surfaces with detergent until it is cleaned. It can be put into use after it is clean.

2. Adding materials: Add food, water, etc. to the pot.

3. Turn on the power: Press the "motor start" switch, the green button, and the stirrer starts to stir. Choose low speed first, and then choose high speed or low speed according to cooking requirements. It is strictly forbidden to adjust the speed of the reducer when the motor is stopped.

4. Burner ignition: The first step is to confirm that the knobs on the operation panel, the long open flame knob and the ignition rod knob are in the fully closed position, and then open the main gas valve. The second step is to turn on the ignition rod knob, ignite the ignition rod, and insert it into the ignition port at the lower part of the combustion chamber. At the same time, turn on the long open flame knob to ignite the long open burner. The third step is to pull out the ignition rod, close the knob, and place the ignition rod in place. The fourth step is to push down the knobs of the fire plate and turn them to the fully open position. At this time, the fire plate burner will ignite automatically. The inner ring burner should be used first, and the outer ring burner should be used after confirming that the combustion state is good.

5. Firepower adjustment: If you need to use a low fire to cook food, you can turn the inner and outer ring knobs from the fully open position to the low fire position by half a turn, or turn off any burner.

6. End operation: After the food is processed, stop heating, return the main burner knob and the long open flame burner knob to the off position, turn off the gas main knob, and press the "motor stop" switch at the right time, the red button, the stirrer stops stirring , Then turn off the main power supply.

7. Dumping operation:

◆ The dumping operation should be performed after turning off the burner and turning off the power supply! Shake the rotating arm handwheel to turn the blender to the proper position; then shake the tilting pot handwheel, rotate the pot to the proper position, and pour the food into the container.

◆ Turn the water tap out of the pot before pouring the pot!

◆ The tilting operation should be carried out slowly, not too fast or too hastily, so as to avoid splashing and scalding hot soup!

◆ Do not put your hands or other objects in the middle of the moving parts to avoid pinching or jamming!

◆ When dumping the jacketed cooking kettle, operate on the front right side, and do not stand behind to avoid crushing injuries!

Use and operation: (1) Installation

1. Place the equipment in a well-ventilated room during installation. The ground is required to be flat and solid, the size of the ground is appropriate, and there is enough space for personnel to operate; after the equipment is placed in the pre-selected site, the pot body should be leveled by adjusting the fixed feet to ensure stable and reliable work, and fixed with anchor bolts.

2. There should be a trough with unobstructed drainage under the equipment, and cold and hot water pipes should be installed on the side of the pot to facilitate adding water and washing the pot during cooking.

3. Connect the gas pipeline. Before starting the gas piping operation, confirm that the supply gas is the same as the gas used in the jacketed cooking kettle; the connection to the gas pipeline must be carried out by specialized technicians. After the connection is completed, the gas pipeline connection should be leak-checked to ensure that the gas pipeline is tight and leak-proof gas.

4. Adjustment of gas pressure. The gas pressure should be adjusted according to the following table before use. In addition, it should be confirmed that the dynamic pressure of surrounding gas appliances should meet the requirements when they are used at the same time. Gas type Rated working pressure (Pa) Liquefied petroleum gas 2800 Natural gas 2000 Artificial gas 1000 5. Check that it is equipped with a standard power socket that meets the requirements, and that it has a standard grounding protection system and is reliably connected to the grounding bolt of the equipment.

Excellent equipment to improve the quality of food processing, shorten the time and improve the labor environment. In terms of the mixing method, it is divided into two types: scraping bottom mixing and planetary mixing. Different mixing methods can be selected according to the specific products.

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:https://www.firemixer.com/

WhatsApp/Wechat:0086 13153609533

Tel:0086 13153609533

E-mail:rena@loneze.com

Address:Zhucheng Economic Development Zone, Shandong Province, the first five lines west

Contact:Ms. Rena

If you have any question you can contact me ,i can give you the lowest discount.